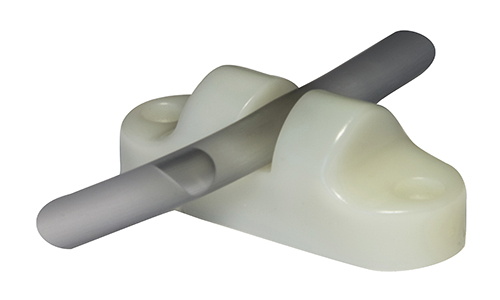

TE Connectivity has a simpler ultrasonic air bubble detector

TE Connectivity has fine-tuned its AD-101 ultrasonic air bubble detector by making its electronics less complex.

Using analytics to model the behavior of the device’s ultrasonic waves, the company’s engineers altered its sensors so they could drastically simplify its printed circuit board, explained Susan Zaks, product manager for TE Connectivity (Schaffhausen, Switzerland). The ultrasonic waves detect air bubbles in infusion lines, which deliver fluids to the body. If allowed to enter the bloodstream, these bubbles could cause a heart attack or a stroke.

“We modeled it using finite element analysis so we could predict the behavior of the ultrasonic waves so we could reduce the electronic complexity,” Zaks said. “It’s all in the modeling.”

The refined bubble detector may be used as part of any manufacturer’s infusion pump or dialysis machine. Upon detecting a bubble, it produces a flashing red LED signal. The sensor output can also be used to generate a sound alarm for a nurses’ station.

Although the PCB was designed specifically for air bubble detectors, the company has used the same analytical methodology to design other sensors for improved performance and to hasten the development cycle. For example, TE Connectivity is using the same modeling process to design new ultrasonic-level sensors to detect the liquid level in a container. Simplifying the circuit board has also reduced prices significantly, Zaks added. She declined to reveal prices, saying they depend upon order volume.

“To offer competitive performance at this big of a cost advantage is a big deal,” Zaks said. “And it opens up some huge markets that we weren’t looking at before.”