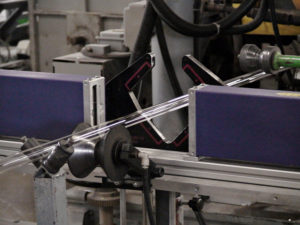

Marposs this week launched its Aeroel Extuline laser measuring system for diameter control and flaw detection of opaque or transparent extruded products.

The measuring system is designed for products such as medical tubing, glass pipes, sections, and electric cables. It features an on-line diameter measurement and automatically prevents the production of out-of-tolerance products by detecting and locating diameter flaws alone the product’s length, according to the Bentivoglio, Italy-based company.

Marposs’s system also features non-contact technology that enables the measurement of moving products that are hot or soft without damaging the product. It signals an alarm for out-of-tolerance conditions to reduce scrap and the risk of rejects later in the process.

Extruline can measure the diameter and ovality of stock from 0.05mm to 149mm using a single or dual-axis laser gauge that depends on the diameter range and the type of product. The gauge is installed after the extruder head and eliminates contact with the guiding role and results in faster and more effective regulation.

With straightforward operation equipped software, Extruline offers guided menus to ensure maximum ease of usage. It also includes Glass Logic, a high-performance software developed by Aeroel to provide reliable gauging of transparent products like glass pipes and medical tubing.

In addition to the company’s three single-axis Extruline X models, Marposs also offers two double-axis Extruline XY models with repeatability that falls within ± 1 and ± 3.5 µm (for single-shot repeatability (±2σ)), according to the company.

All Extruline X laser systems are pre-loaded with software for ease-of-use and are simple to program. Users can also connect a printer to the CE-200 panel to print a copy of a complete statistical report.