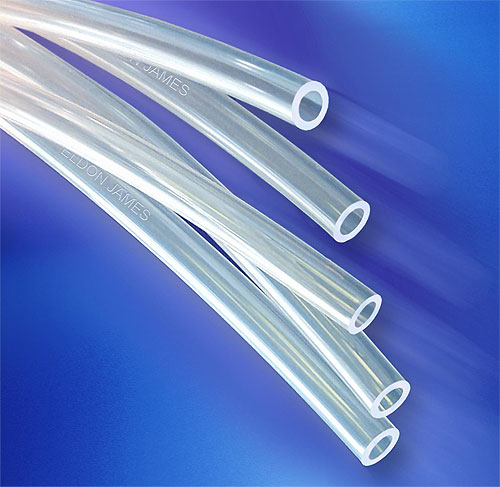

Eldon James’ strong commitment to technological innovation and anticipation of customer need led to the development of a new line of tubing and fittings designed to meet end-user demands for improved cleanliness and environmental responsibility without sacrificing flexibility, clarity or durability. GLS custom TPEs not only meet these criteria, but also offer a wide range of Shore A hardnesses that allow the same formulation to be used in both flexible tubing and rigid fittings. These grades, which are based on a newly developed material technology, streamline the qualification process and also simplify disposal for end users because the components do not require disassembly.

GLS custom grades enable the product line to meet environmental compliance regulations such as the European Union’s Restriction of Hazardous Substances (RoHS) directive. These custom elastomers also feature extremely low leachables and extractables for patient safety, and higher-hardness grades can withstand autoclave sterilization at temperatures up to 135ºC.

These custom TPEs provide the following additional benefits:

–Excellent flexibility for kink resistance and good drape

–Range of Shore A hardnesses from 66 to 84

–USP Class IV approved

–Incineration without release of hazardous chemicals

–Sterilization with autoclave, gamma and E-Beam radiation

–Exceptional clarity and quality consistency

PolyOne

www.polyone.com

::Design World::