David Bach / BST-Bach Solutions & Technology, LLC

Accurate dispensing affects a great deal of drug development and delivery. For instance, leading-edge pharmaceuticals, bio-tech “designer molecules” and high-potency compounds are tremendously expensive and come with difficult safety concerns that require accurate dispensing and aspirations. Many of these compounds are composed of proteins or synthetic molecular chains that are extremely fragile and highly susceptible to shear. In addition, setup time must be reduced, and maintaining the product within a dispensing tube must meet or exceed safety and contamination concerns. For these reasons, peristaltic pumps have found wide application.

The basics

Hospitals use peristaltic pumps to circulate blood during bypass surgery and as a critical part in heart-lung machines because the pump’s design does not cause significant hemolysis–the rupture or destruction of red blood cells.

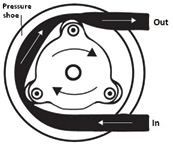

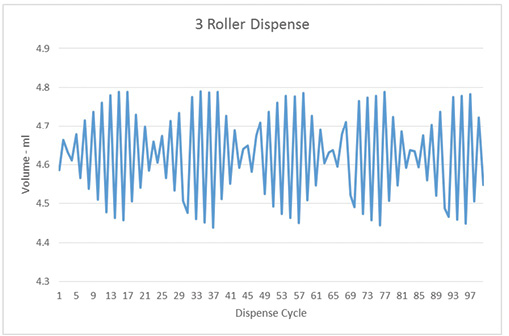

The design uses a compressible polymer tube to hold the fluid that requires dispensing. The arrangement also allows pumping aggressive chemicals, slurries with a high solid content and other materials when it is critical to isolate the fluid from the environment. However, the peristaltic pump suffers from pulsations because its rollers move on and off a pressure shoe as the tube is compressed. The pulsations plotted in 3 Roller Dispense can be reduced by adding more rollers to a peristaltic pump. Although, there is a better idea.

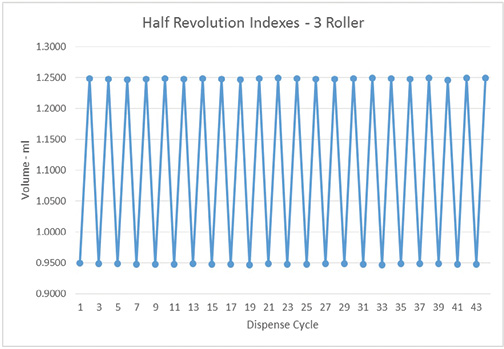

If the peristaltic pump can start each dispense with one roller in the same starting position, the amount of fluid-dispensing variance can be greatly reduced. When the pump has three rollers and the starting position is repeated every 180°, the plot in Half Revolution Indexes, shows the two positions representing half and full revolutions.

A solution for fluid accuracy

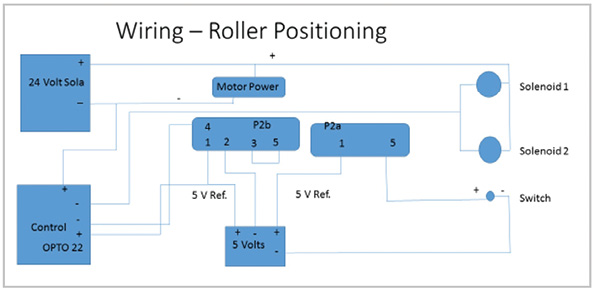

The Lexium MDrive, an integrated solution, includes signal inputs and outputs for roller positioning. The design allows dispense volumes made from multiple revolutions plus some fraction of a revolution. Roller positioning takes into consideration the fraction of a revolution and ignores the complete revolutions. External valves are used so the peristaltic pump can dispense fluid and then control the starting position of the next peristaltic roller without dispensing. Connecting a Lexium MDrive motor according to the accompanying electrical diagram lets it dispense and then control the valves so the rollers are positioned to the same starting point for each dispense cycle. This allows dispensing a precise and repeatable quantity.

When the number of peristaltic rollers does not divide evenly into the number of microstepping-motor counts, a round-off error occurs. For example: A three-roller system will not divide without a fraction into 51,200 microsteps per revolution. The number of steps between rollers would be 17,066.6667 steps. The motors will only recognize 17,066 steps for each of two rollers and need to add 2 steps to the final roller, making it 17,068. Each dispense must end with the total movement of rollers equaling 51,200 steps per revolution. Each move during the dispense cycle can be verified by using the motor encoder. When the Lexium MDrive is set to MS = 180 it will use 36,000 steps per revolution, allowing even roller divisions. There are up to 20 software-selectable resolutions within the Lexium MDrive.

A few pump and valve setups

The circuit described in A in A few pump and valve setups, uses an external pinch valve as a normally open dispense and normally closed position valve. One of the rollers is positioned relative to the encoder Z pulse. The pump dispense is selected and fluid would then be dispensed. A drip retention is used to bring the fluid back into the tube so that closing the dispense valve does not cause a drip. The dispense valve is then closed, and the position valve opened. The next roller is moved into the same position as previously used for dispensing. This will result in a small amount of fluid waste. After the first roller position move, the next roller can be positioned either in a positive or negative direction, minimizing fluid waste. Using the various directions for roller positioning minimizes fluid waste.

The system shown in B represents a two-tube peristaltic system in which the rollers are offset and the two tubes combined. A six-roller system effectively becomes a 12-roller system, minimizing pulsations. Both peristaltic tubes are combined using an “x” connector, where one leg becomes the waste tube. The dispense valve must be placed after the dispense tube “x.” The roller positioning takes place with the dispense valve closed and the position valve open. The pressure shoes could be different, so it is recommended that one tube-and-shoe combination be used for roller positioning.

For system in figure C, a robotic arm would move the pipette tip to a microtitre plate. The tip just enters the fluid and track its level while fluid is removed. The tip then moves from the fluid and drip retention is applied before moving it. At the delivery position, fluid is removed and blown out by positioning the roller to the starting point. The tip could be exchange and the process repeats.

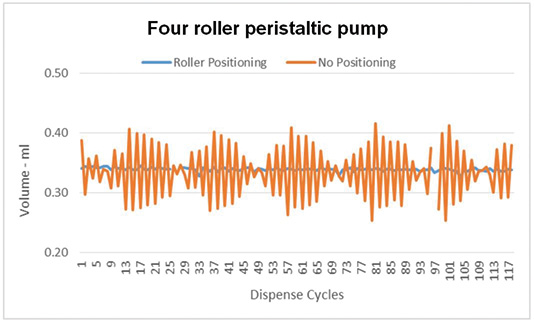

Four-roller configuration: Watson-Marlow 313 pump

A four-roller pump is used with a series 23 Lexium MDrive motor and two Bio-Chem pinch valves. The on-and-off switch allows a standby configuration. The motor drive is coupled to the pump using a Helical coupling, or equivalent, so that reverses do not adversely affect performance. The mounting block between the motor and pump controls heat transfer.

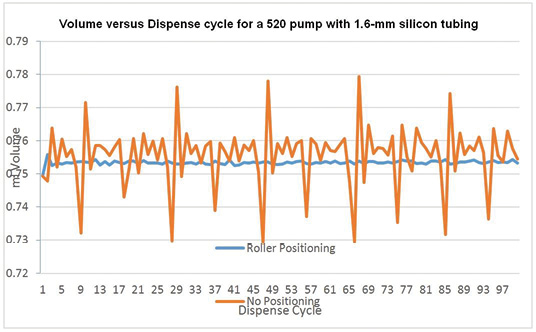

Two-roller configuration: Watson-Marlow 520 pump

The plots in Volume versus dispense cycle show an embodiment of a system that uses a Lexium series 34 ac motor drive. A small tube was used along with the Bio-Chem pinch valves and a similar coupling.

Summary

Various pumps, valves and motors can be used for roller positioning, depending on the application. It should be noted that starting in the same position works extremely well for through-the-pump applications as well as aspirations into a pipette tip or other device such as a flow cell. BST offers roller positioning for any peristaltic-pump system that needs greater dispensing accuracy. The use of peristaltic pump systems, pinch valves, and integrated motor/motion lets the BST approach solve accuracy problems opening up new peristaltic opportunities.

BST has filed a United States patent for the use of roller positioning. The motor systems can also be configured to use an optical or proximity device for control for a correct roller position.