Teknor Apex now offers a comprehensive portfolio of medical-grade tubing compounds, including Apex flexible PVC, Flexalloy PVC elastomers and Medalist thermoplastic elastomers (TPEs). In addition, the company has developed Apex SCR stress crack resistant rigid PVC compounds for tubing connectors.

In addition to the DEHP-containing compounds that have long been the industry workhorse for tubing, the Apex line of PVC tubing compounds now also includes multiple non-DEHP- and non-phthalate-plasticized formulations, including high heat-stable products.

The Apex line of tubing compounds includes gamma-stable formulations. For especially demanding applications, such as tubing requiring high tensile strength, abrasion resistance or kink-resistance at low durometers, Teknor Apex also offers Flexalloy compounds, which are based on high molecular weight PVC polymer.

The Apex line of tubing compounds includes gamma-stable formulations. For especially demanding applications, such as tubing requiring high tensile strength, abrasion resistance or kink-resistance at low durometers, Teknor Apex also offers Flexalloy compounds, which are based on high molecular weight PVC polymer.

Apex rigid PVC products are available for molded tubing connectors. The newest of these are Apex SCR compounds, which provide strength comparable to polycarbonate (PC) or ABS and excellent clarity while reducing or eliminating the stress cracking that often occurs in PC or ABS at the interface with flexible PVC tubing. Gamma-resistant grades are also available.

Teknor Apex has recently expanded its portfolio of Medalist elastomers, now offering suitable alternatives to PVC, silicone, and TPU for medical tubing.

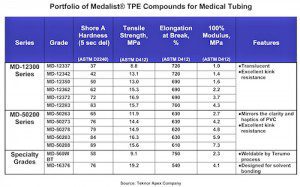

The Medalist product line for tubing includes 13 standard and specialty compounds, ranging from 37 to 83 Shore A and covering a broad spectrum of physical properties. Medalist elastomers are ISO 10993-5 compliant and plasticizer-free, with a low level of extractables. They can be sterilized by e-beam, gamma, ethylene oxide (EtO) and steam (autoclave). These grades are good candidates for single and multi-lumen tubing for catheters, IV, drug delivery, gas supply and chest drainage.

Medalist tubing compounds meet such functional requirements as kink resistance, clamp resilience and resistance to “necking” when subjected to longitudinal force, according to Ross Van Royen, senior market manager of regulated products for the Thermoplastic Elastomer Division.

Medalist tubing compounds meet such functional requirements as kink resistance, clamp resilience and resistance to “necking” when subjected to longitudinal force, according to Ross Van Royen, senior market manager of regulated products for the Thermoplastic Elastomer Division.

The newest of the Medalist tubing compounds is Medalist MD-16376, an optically clear 76 Shore A compound designed for solvent bonding to connectors. Solvent bonding is one of the major reasons why medical device manufacturers were slow to accept TPEs in tubing applications, noted Mr. Van Royen.

In developing Medalist materials for tubing, Teknor Apex worked with medical industry experts, processors, and equipment suppliers to ensure that downstream processes like hole cutting, tipping and printing would not be an issue. Teknor Apex can provide suggestions on which processes work best on Medalist materials.

Teknor Apex

teknorapex.com