Biocoat officials say their Hydak coatings deliver competitive durability and lubricity — and they’re made out of a naturally occurring substance.

Better yet, Hydak offers extremely low particulate counts, according to the company. Plus, it’s made out of something that’s already in the human body: hyaluronic acid (HA), a naturally occurring polysaccharide.

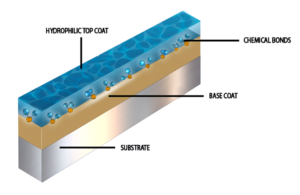

Biocoat applies its Hydak coatings using a thermal heat curing system in which it places coated items in an oven for a predetermined time. The controlled heating accelerates drying of the solvent and any necessary chemical reactions taking place within the coating, enabling a better surface bond and durability, according to Biocoat. The consistent and uniform bonding from the thermal heating system means that it’s possible to coat both the inner and outer diameter of a catheter device.

Biocoat officials acknowledge that the high levels of lubricity and durability that hydrophilic coatings offer are not always required for some procedures and devices. However, they argue that premium performance will greatly benefit catheter procedures designed to treat life or death cases, such as in cardiovascular and neurovascular applications.

“Could you get a neurovascular catheter from your groin to your brain using one of those additives or Teflon? Absolutely. Is it going to be more difficult for the doctor? Yes. Is it probably going to be more difficult for the patient to recover? Yes,” Bob Hergenrother, senior director of R&D at Biocoat, told Medical Tubing + Extrusion and Medical Design & Outsourcing.

Here are the four main variables that Hergenrother suggests evaluating when it comes to deciding what type of lubricious coating to use in a catheter application:

1. Particulates

Government regulators are scrutinizing, in fact demanding, particulate data from medical device companies. The count of foreign materials left in the body after a device is used is extremely important when it comes to patient safety, Hergenrother said.

2. Friction

Doctors performing procedures that include a catheter consider “low friction” as a must-have because it directly impacts ease of use, according to Hergenrother. It also serves to reduce patient discomfort and may improve healing, with shortened procedure times.

3. Durability

When it comes to catheter-based cardiovascular or neurovascular procedures, there can be many twists and turns on the route to the targeted area of interest, so a coating needs to maintain consistent lubricity while remaining durable throughout the procedure, Hergenrother said. In theory, the more durable the coating, the less particulates generated.

4. Pricing

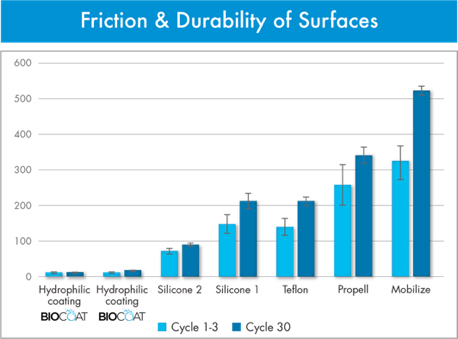

Biocoat officials acknowledged that hydrophilic coatings may be more expensive than other lubricious materials. However, they say the overall performance and safety profile that hydrophilic coatings offer justify the higher pricing model. The difference in overall performance can be seen in the following chart, which shows the overall performance of the different types of lubricious materials.

In this chart, the Biocoat R&D team tested several types of lubricious coatings that are typically used to minimize friction on interventional medical devices. The tested coatings include Biocoat’s Hydak hydrophilic coating, extrusion additives, silicone oils and polytetrafluoroethylene (PTFE).

To complete this test, the Biocoat R&D team performed a pinch test and recorded the results after testing cycles 1-3 and after cycle 30 to determine the initial friction and overall durability of the coating material. The materials coated with Biocoat’s Hydak coatings had significantly better lubricity and durability counts than any of the other tested materials, according to the company.