More electrodes and thinner electrodes were always goals at Medtronic. But neuro device makers across the industry have faced the difficulties of developing chronic implants for stimulation, as well as designing interconnects to bridge the implants with the rest of the physical system.

“I think we’re on a good path to be successful” at Synchron, Banerjee said in an interview with Medical Design & Outsourcing in 2023 before she was promoted to CTO.

Related: Synchron’s plan to beat Neuralink in the neuroprosthetic BCI race

For one, while Synchron designed its BCI system for permanent implantation, it only senses brain signals and doesn’t stimulate. And Synchron believes it has solved the interconnect challenge with a lead that connects its electrode-stent Stentrode brain implant to the implantable receiver telemetry unit (IRTU) in a patient’s chest.

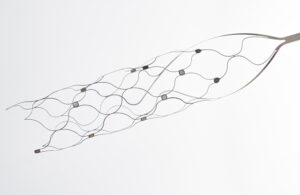

So Synchron starts with a stent — or at least what looks like a stent. The Stentrode doesn’t need to prop the vessel open or resist external crushing forces, but uses the tubular shape to stay in place inside the blood vessel where it senses brain signals.

“It’s paramount that it’s safe. You can’t get approval to do anything until it’s safe, so foundationally it has to be safe, but it doesn’t have to be manufacturable,” she said. “You can hand build 10 units for clinical study, you can have a technician in Minnesota handbuilding something and as long as you can inspect quality and you can demonstrate that it’s safe.”

“Early on, when you’re doing a few patients, that’s the starting point,” she later continued. “And then [it’s] how do you make it manufacturable? … The early story of Synchron is really just taking existing stent technology and putting electrodes on it.”

Instead of a laser-cut tube to provide physical support to the vessel like a traditional stent, Synchron manufactures its Stentrode implant with a thin-film process that prints layers of nitinol and layers of insulation contacts that serve as electrodes.