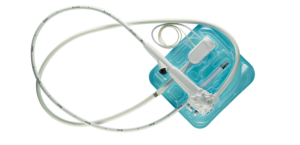

1. Ambu: aScope Duodeno disposable endoscope

Ambu received FDA regulatory clearance for its aScope Duodeno single-use duodenoscope in July last year.

Ballerup, Denmark-based Ambu says it designed the aScope Duodeno to streamline workflow with no reprocessing or repair. With no spare parts, the duodenoscope is ready to use by opening its packaging and connecting the duodenoscope to Ambu’s eBox Duodeno unit, which connects directly to medical-grade monitors to process the camera’s video image.

“A key benefit of single-use versus reusable is the ability to do fast innovation — in months and not years. And the new technology gets in the hands of the doctor quickly because the next shipment can be of the latest product and there is no upfront capital investment,” Rasmus Kümmel Holtze, director of Ambu global product management in gastroenterology, told Medical Tubing + Extrusion. “Ambu’s vision is to enhance patient safety, eliminate device-related cross-contamination, and simplify the procedure set-up. Since aScope Duodeno is single-use, there is no degradation of mechanical performance over time – it is always a new scope, sterile straight from the pack and available.”

The sterile, single-use duodenoscope has high definition imaging with a camera that connects to the accompanying aBox unit to give physicians a clear image of mucosa and anatomical structures in the upper GI tract. It also features dual LEDs in the distal tip with a 130º wide field of view; a rounded tip design; four-way bending angulation allowing distal end bends up 120º, down 90º, right 110º and left 90º; three programmable remote switches and a 4.2mm working channel.

“For the users, a single-use duodenoscope will feel different, more lightweight, than a reusable, and doctors have to get used to a different sensation,” Holtze said. “However, those differences are minimal versus the ability to protect patients from cross-contamination, improve hospital efficiencies, and add convenience with full cost-transparency, no upfront capital investment, no repair cost and no time-consuming reprocessing that impact workflow.”