Virtual tubing model analysis optimizes catheter design to help engineers reach final design freeze faster and shorten time to market.

As medical procedures become more complex, engineers are challenged to develop smaller, thinner-walled catheters to keep pace with high-performance clinical demands. Conventional catheter prototyping relies on a manual, time-consuming trial-and-error process involving multiple rounds of material procurement, prototype assembly and bench testing. A virtual simulator simplifies the catheter design process but is still time-consuming and has resource challenges.

Using a virtual tubing model analysis – such as Integer’s proprietary Virtual Tubing Model software (VTM) – dramatically decreases the time and resources needed for physical prototyping. With VTM, complex multilayer braided composite tubes can be modeled in minutes, compared to using 3D CAD modeling programs that may take hours and consume valuable time.

(Network with Integer experts at DeviceTalks West, Dec. 11–12 in Orange County, Calif.)

Here are three ways the Virtual Tubing Model software helps speed catheter design:

1. Rapid design modeling

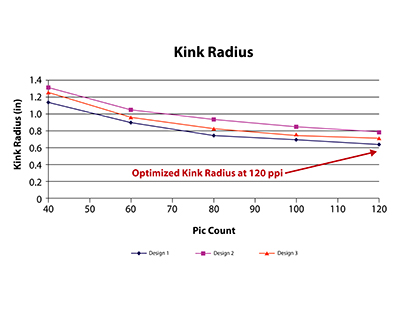

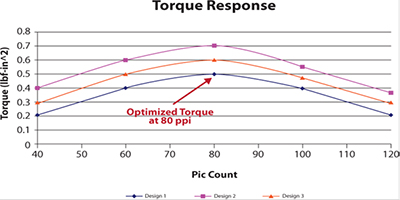

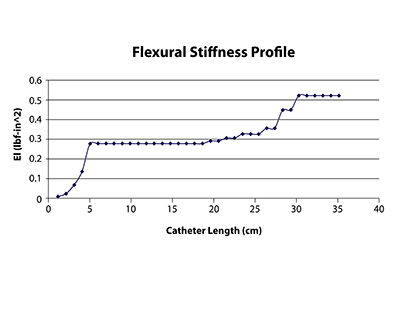

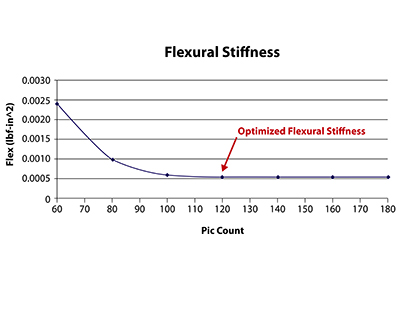

With VTM, engineers can quickly model design options to predict kink radius, bending (lateral) stiffness, linear stiffness, torsional stiffness and hoop strength. Various design options can be modeled and overlaid in graphical form for each performance attribute, allowing engineers to analyze the graphs simultaneously to determine which design delivers optimal performance and any tradeoffs.

For example, an engineer may want to maximize kink response, but doing so may greatly reduce the torque response of the shaft. Knowing the tradeoffs in advance is crucial to developing a catheter shaft that delivers optimal performance.

2. Adaptable design options

3. Design for Manufacturability (DFM) analysis

Based on a 20-year history of optimizing catheter designs, Virtual Tubing Model software is one of the most effective tools available today to predict prototype performance. The ability to create and overlay multiple reports for different design iterations allows engineers to identify performance patterns and pinpoint an optimal design more quickly. The result is significantly fewer prototype iterations to reach final design freeze and enhanced speed of new product delivery to market.

Michael Holt is technical solutions director at Integer (Frisco, Texas). Holt has more than 20 years experience in the design and development of complex catheter based devices. He holds a Bachelor of Science in mechanical engineering from the University of Tennessee.