Articulating instruments that include metal tubing offer more bend, flex and reach – and thus more freedom for surgeons who require minimally invasive tools for minimally invasive procedures.

Steve Jacobsen, Micro

Adding functionality to instruments with tubing means that greater attention to detail is necessary during design planning, especially before development, to avoid challenges and pitfalls.

That’s why design for manufacturability, or designing products so that they’re easy to make, is extremely important. DFM allows potential problems to be identified and addressed during the design phase, which can save money and wasted resources in the long run. Product design engineers many times find themselves facing a dilemma, from cost, time or other factors, and dismiss manufacturing considerations – which could prove detrimental in producing the parts.

Here are some challenges to keep in mind when laser-cutting metal tubing to achieve articulation. It’s possible to rectify all of these in the design phase, before a first build.

1. Cutting approach

There are advantages and disadvantages to the laser-cutting or machine-cutting of metal tubes, including application requirements, cost-effectiveness and production capabilities. With articulating instruments (which involve shaping and forming materials, including milling and drilling), there can be a considerable cost involved if errors in design are missed and not addressed early on.

2. Design for articulation

Before the development of articulating instruments, it’s prudent to weigh the options, including the number of times a tube must articulate and to what degree, the amount of fatigue it will undergo, the temper a tube needs to be, the effect of stress concentrators, and the impact of cold-working the material.

3. Slugs

Articulating instruments are built to have flex and bend capabilities; therefore, there will inevitably be unwanted pieces of metal (slugs) that are cut and removed from tubes to allow for independent movement. If these slugs, which can be as small as a human hair, are not properly controlled, they can cause issues for both the machine they are cut on as well as the product itself. Precise design certainty is imperative.

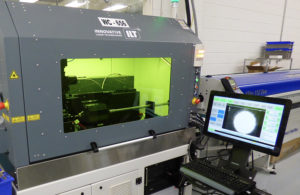

Volume and costs play a significant role in determining the best technology to use to help with slug control and mitigation in tubing development. The ultra-short-pulse femtosecond laser, for example, is ideal for cutting plastic and extremely thin stents – virtually no heat is transferred into the part due to the short pulse, which vaporizes the material completely. While these lasers have their advantages, they are infinitely slower and naturally cost more. A solid-state cutting laser with millisecond pulse durations is more cost-effective and best for disposables. Although this method will produce slugs, because the only material removed will be that of the beam diameter, there are techniques and technologies to ensure that they’re easily and efficiently removed from the tubing.

4. Programming

Laser cutting articulated tubes poses specific challenges that can be mitigated with the proper programming techniques. Traditional methods adopted from CNC milling and turning don’t directly translate to laser cutting of thin-walled articulating components. Laser focus and power output modulation are some of the process parameters that must be optimized to ensure efficient cutting.

Cut geometry and laser feed rate are also very important. A programmed cutting path that’s the most efficient for a particular cut may not be efficient for the removal of the resultant slug. The section to be removed can lock or entangle itself within the base component, requiring multiple passes to break the cut up into smaller sections.

Conclusion

For single-use disposable devices, a high-end femtosecond or picosecond laser is not necessary. Although a standard laser-cutting machine produces slugs from tubes, it’s much less expensive. And, with the right manufacturing process, the impact of these slugs can be mitigated with programming and machine additions (e.g., magnets). Partnering with an experienced CMO with manufacturing expertise and historical product knowledge can extract the most value from a DFM approach.

Steve Jacobsen is process development engineering manager at Micro (Somerset, N.J.), a full-service contract manufacturer. Micro draws on 70 years of experience in medical device assembly, precision metal stamping, insert and injection molding, machining, sharpening and finishing to deliver products to customers in a variety of industries including medical device, automotive, aerospace and electronics.